Lubrication of crane equipment

Vibration, heavy mechanical loads, contamination, and humidity reduce the service life of bearings. Like any mechanical system, deck crane slewing bearings and cantilever arm pulleys require proper lubrication to maintain proper performance.

SKF and Lincoln automatic lubrication systems ensure precise and timely delivery of lubricant in the required quantity during equipment operation without the need for shutdown. Automatic lubrication systems deliver lubricant over long distances and a wide temperature range, and offer a reliable solution for lubrication in hard-to-reach areas.

Advantages

- Reliable lubrication in hard-to-reach places

- Preventing unscheduled downtime

- Reducing the risk of accidents

- Reducing operating costs

Application areas

- Slewing rings

- Rotary bearings

- Pulleys

- Rail guides

- Cables

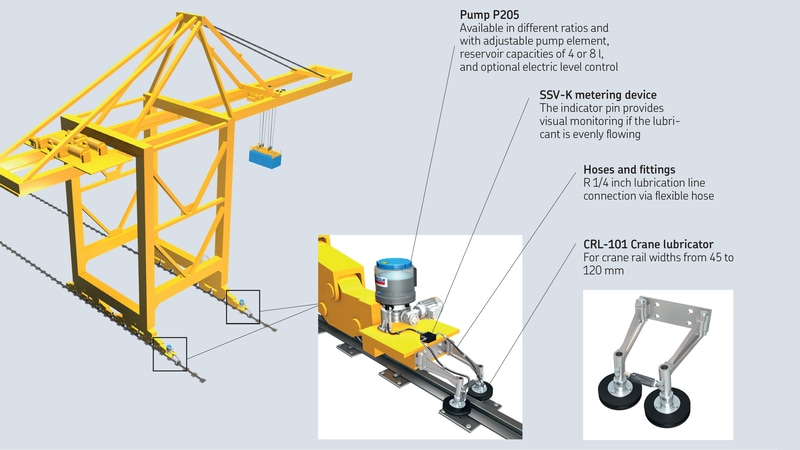

Wheel flange lubrication for slow-moving rail-type cranes

The CRL-101 reduces rail wear, noise and lubricant consumption at harbor cranes, special container handling systems, and overhead and gantry cranes.

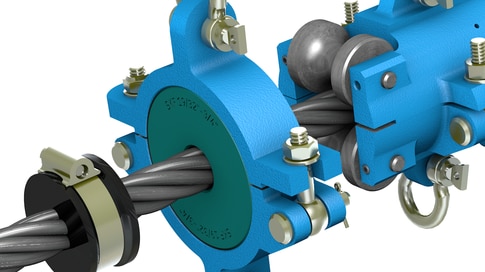

Lubrication of cables

Extended cable life and reduced lubrication time. The service life of a regularly lubricated steel cable is approximately six to eight times longer than that of a cable without lubrication.

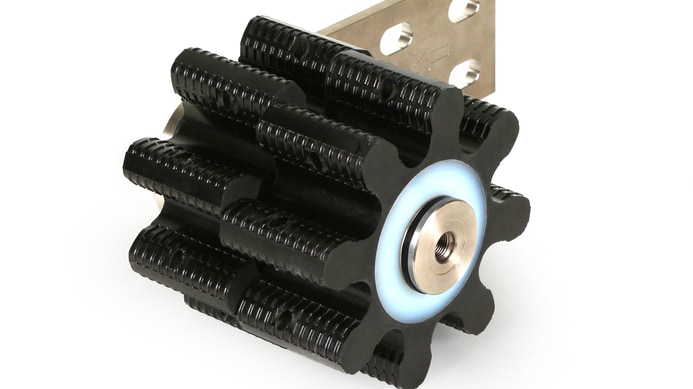

Lubrication of gear teeth and racks

Lube pinions provide contact lubrication for the drive pinions of open gear trains and racks. Lube pinions also lubricate the tooth flanks of open gear trains, such as those found in large slewing bearings or propeller blade bearings. Movement…

Efficiency

Improving crane efficiency

SKF sequential automatic lubrication systems have been installed on cranes at the Mediterranean Shipping Company (MSC) head terminal in Europe's second largest port, Antwerp, Belgium.