010000, RK, Astana,

st. Dinmukhameda Kunaev 33,

office 1003

Mark on the map

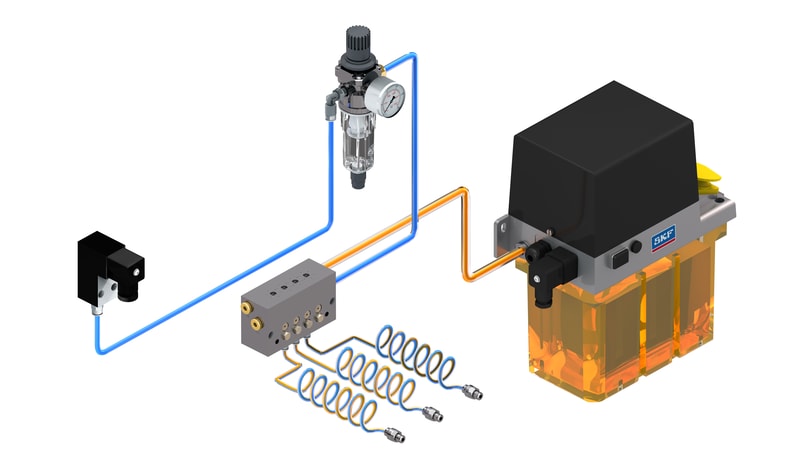

Oil-air lubrication systems

An oil droplet is broken into pieces by a stream of air in a narrow tube. The oil is then transported toward the lubrication point. Fine oil droplets are continuously fed into the bearing from the outlet nozzle. The conveying air leaving the bearing is virtually oil-free.

Oil-air lubrication systems can be upgraded to suit individual requirements and equipped with innovative sensors to monitor the continuity of oil flow.

Advantages

Application areas

In oil-air lubrication systems, a metered volume of oil is drawn into a constant air flow in a pipeline. It moves along the pipeline wall in the direction of the compressed air flow. At the mixing point (mixing valve), a volume of oil is directed into the air flow in pulses. A virtually continuous flow of finely dispersed oil droplets is delivered contactlessly from the outlet nozzle to the bearing. This means the bearing housing is under slight positive pressure, preventing contaminants from entering the bearings.

The conveying air leaving the bearing is virtually oil-free. This concept eliminates oil mist, further enhancing the system's environmental friendliness.

010000, RK, Astana,

st. Dinmukhameda Kunaev 33,

office 1003

Mark on the map