Plastic lubricant injection systems

For roller and stamped chains

Every link matters

Every link in a chain is important: hundreds or thousands of lubrication points are in constant motion. Chains operating in harsh conditions require frequent relubrication to reduce the risk of failure. Unscheduled production shutdowns due to chain failure are unacceptable. Any unscheduled maintenance impacts the final results. Manual lubrication can put personnel at risk. This is a labor-intensive procedure, often performed insufficiently frequently, and can lead to loss of control over lubricant consumption. Personnel are the top priority. Furthermore, contamination of products with lubricant is also unacceptable.

What if you could:

- Improve occupational safety?

- Lubricate chains at the required frequency without stopping production?

- Increase chain life and eliminate the risk of production stoppages caused by chain failure?

- Control the consumption of plastic lubricant?

- Avoid downtime caused by the need for unscheduled maintenance?

Selecting the Right Lubrication System

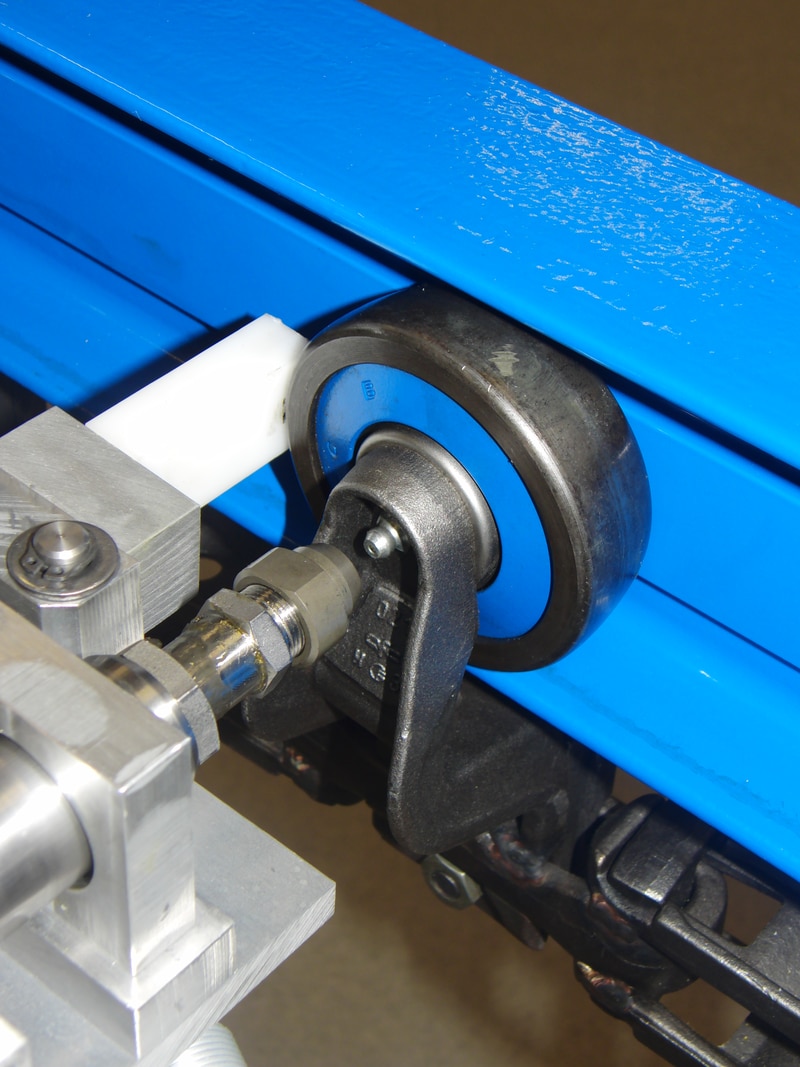

Conveyor guide rollers

For monorail conveyors with stamped chain, the GIS grease injection system injects grease into the guide rollers via unique grease nipples while the conveyor is moving.

GIS systems can be adapted to various conveyor configurations and applications, including lubricating chain guide rollers or carrier rollers (both driven and non-driven conveyors). GIS systems for guide rollers allow for the simultaneous lubrication of two guide rollers or multiple carrier rollers.

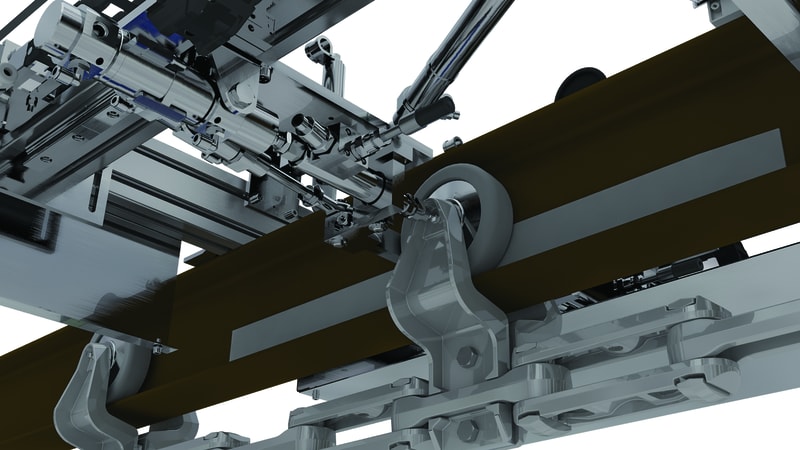

Double outer roller chains

For dual-chain conveyors, GIS systems inject grease into the outer rollers on both sides of the chain using unique grease fittings while the conveyor is moving. These systems can be adapted to various conveyor configurations and applications, taking into account the dimensions and components used. GIS systems for dual outer rollers lubricate both chains simultaneously.

Single outer roller chains

For dual-chain conveyors, GIS lubrication systems inject grease into the outer rollers via unique grease fittings while the conveyor is moving. These systems can be adapted to various conveyor configurations and applications, taking into account the size and components used. The GIS system for outer rollers allows for the simultaneous lubrication of both chains.

Internal roller chains

For double-chain conveyors, GIS lubrication systems inject grease into the internal rollers via unique grease fittings while the conveyor is moving. These systems can be adapted to various conveyor configurations and applications, taking into account the dimensions and components used:

- Lubrication of the internal rollers of a "simple" chain with plastic grease (only one lubrication point per link)

- Lubrication of the internal rollers of a «complex» chain with plastic grease (several lubrication points per link)

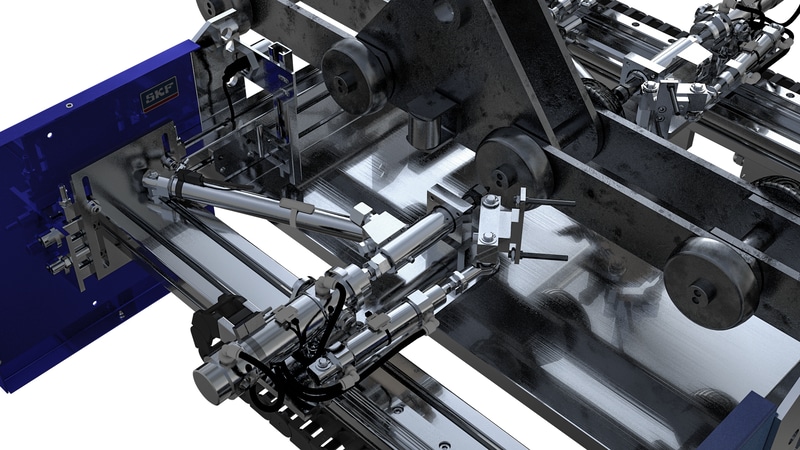

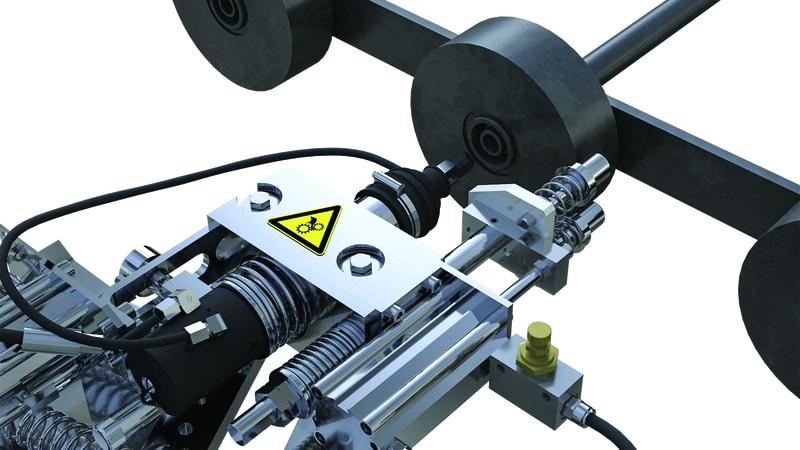

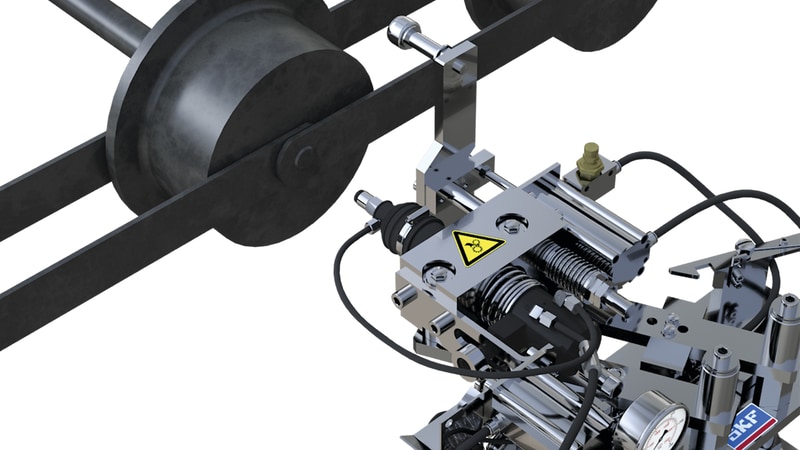

The GIS system for internal rollers allows both chains to be lubricated simultaneously. SKF offers two different conveyor chain lubrication units – both operate on the same principle. The GIS lubrication system operates only when the conveyor is moving. During the lubrication phase, when a roller passes in front of the device, a gripper is activated, mechanically connecting the injector head to the roller. The unit follows the chain, injecting the required amount of grease. At the end of the injection cycle, the head and gripper retract. The device returns to its original position, ready for a new injection cycle for the next roller. A unique feature of the GIS lubrication unit is its ability to follow the chain to lubricate the required points without interrupting the production process. The GIS device is thus attached to the chain. Engagement can be achieved in several ways: using gripper fingers, a sliding lever with a fork, or a winch. The GIS system with the COBRA unit is a simple and reliable solution for chain conveyor lubrication, particularly in heavy industry and harsh operating conditions. The movements required to complete the injection cycle are accomplished using mechanical and pneumatic drive systems. The standard version is activated manually, but versions with automatic activation are also available. A range of monitoring functions can also be integrated into the system. The GIS system with the GVP unit is an advanced solution for chain conveyor lubrication. It automatically manages lubrication cycles. The GIS system can be adapted to a wide range of chain speeds, as well as various conveyor configurations and roller positions.One system, two units

COBRA units

GVP units