Description

For circulating oil lubrication systems

Flow limiters deliver individual, metered streams of oil to each lubrication point in the connected system. These individual oil streams are unaffected by changes in system pressure and are virtually independent of viscosity. This makes them an ideal solution for applications with fluctuating oil temperatures, such as in steel mills or mining. Their self-regulating operating principle eliminates the need for complex pressure control devices.

The SMBM series flow limiter is designed for installation on a support panel as part of modular groups containing from 1 to 6 flow limiters.

Thanks to the use of interchangeable plug-in nozzles, the oil flow can be changed in steps within the range from 0.08 to 8 l/min. (0.17 to 16.9 pints/min). Signal transmitters, piston sensors, or gear flow meters installed within the flow limiters monitor oil flow in each individual device. They are connected to the monitoring unit.

The SMBM series flow limiters replace the SMB 8, SMB 9 and SMB 10 series devices.

Technical characteristics and advantages

- Modular design

- Constant oil flow

- Self-adjusting dosing

- Constant oil flow despite varying back pressure values

- Wide range of lubricant viscosity

- Practically independent of viscosity

- ATEX version available

- Simplicity of system design

- Compact installation

- Easy commissioning, no additional adjustment required

- Effective monitoring of required oil consumption

Application areas

- Pulp and paper industry

- Metallurgy

- Heavy industry

- Tunnel boring machines

Technical specifications

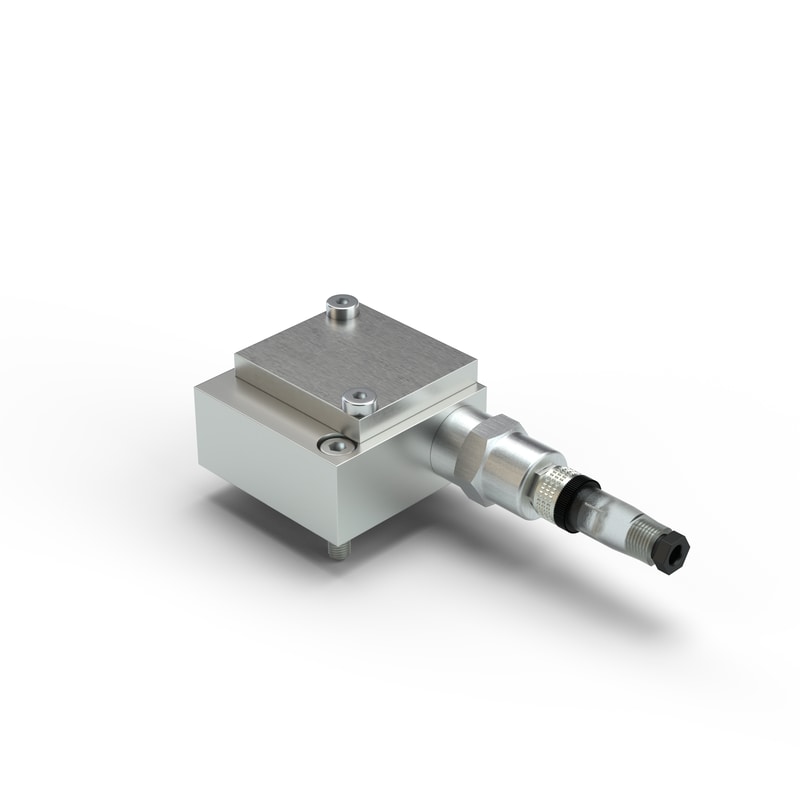

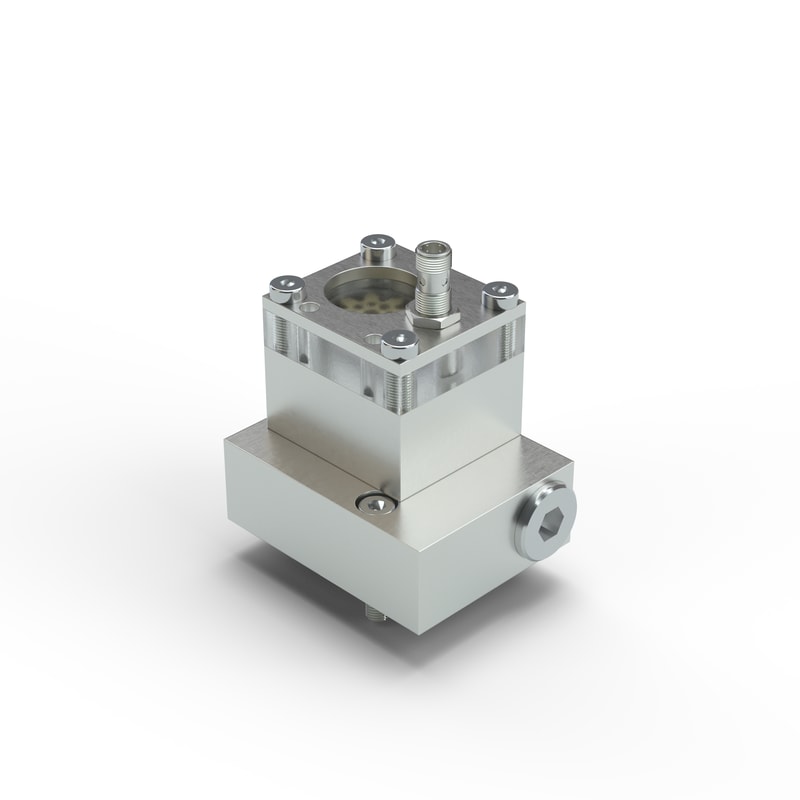

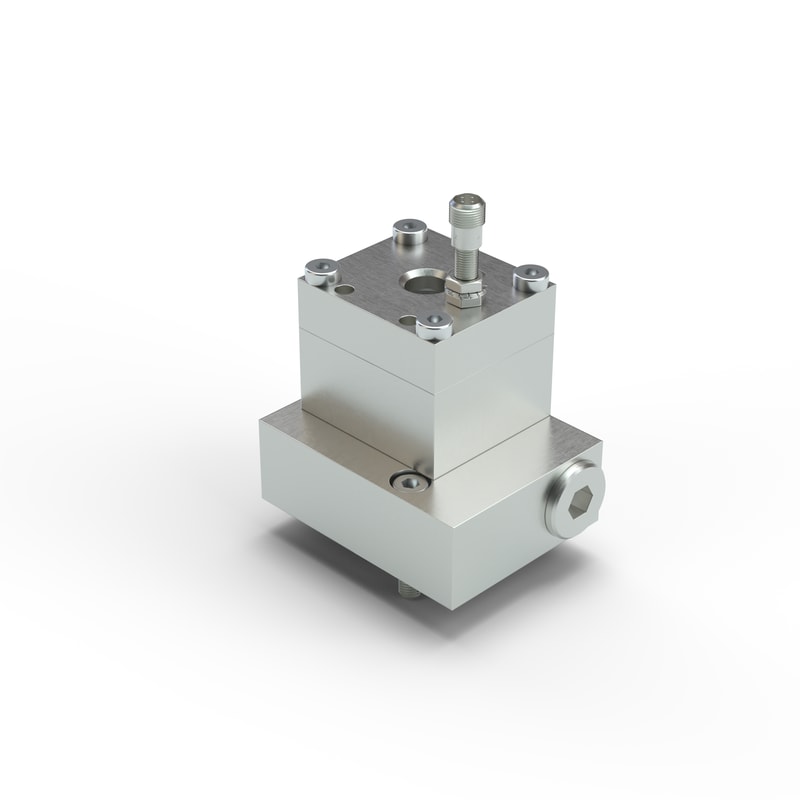

| SMBM-X 21/22 Monitoring with a signal transmitter |

|

SMBM-X 31 Monitoring with a piston transmitter |

|

| Type/operating principle | 2-way flow control valve with one fixed setpoint | ||

| Monitoring type | Signal sensor or piston sensor (signal present/no) | ||

| Installation position | Any (without filter); vertical (with filter) | ||

| Ambient temperature | from 0 to +70 °C | from +32 to +158 °F | |

| Lubricant temperature | from 0 to +70 °C | from +32 to +158 °F | |

| Material | EN AW-6061-T651, anodized | ||

| Weight SMBM-X 21/22 Weight of SMBM-X |

0.87 kg 0.81 kg |

1.92 pounds 1.79 pounds |

|

| Dimensions without monitoring (L×W×H) | 79×79×45 mm | 3.11 x 3.11 x 1.77 inches | |

| Nominal flow rate | 0.08–8.0 l/min | 0.17-16.9 pints/min | |

| Working pressure p1 Without electrical monitoring SMBM-X 21/22 SMBM-X 31 |

5–200 bar 5–100 bar 5–85 bar |

72.5–2900 psi 72.5–1450 psi 72.5–1230 psi |

|

| Required differential pressure (p3-p1) | ≥ 5 bar | ≥ 72.5 psi | |

| Lubricant | Mineral oils, synthetic oils | ||

| Working viscosity | 20–600 mm2/With | ||

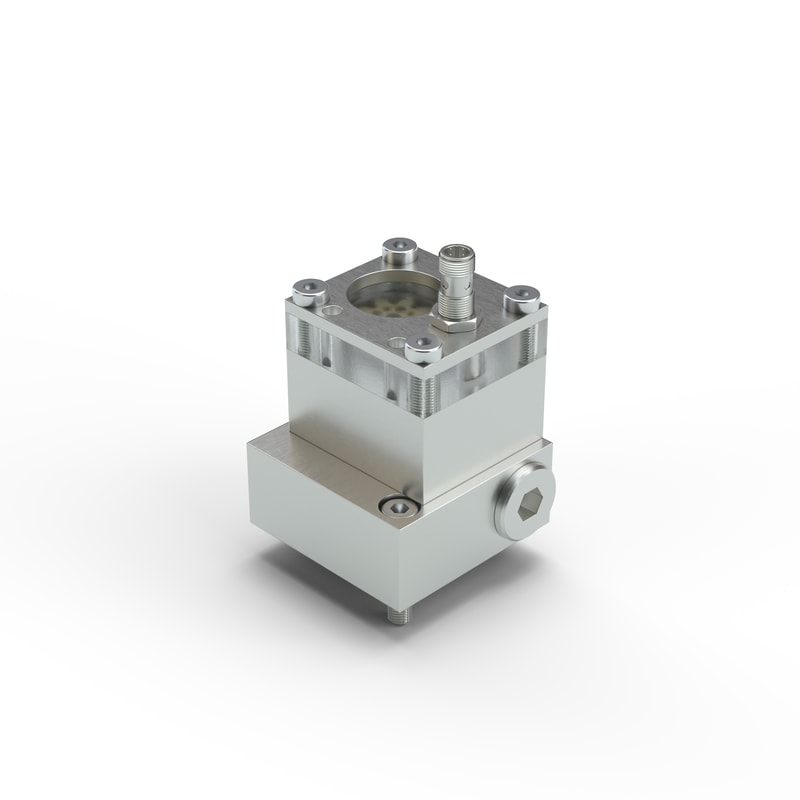

| SMBM-X 11/12/13 Monitoring with a gear flow meter with a threaded pulse sensor |

|

||

| Type/operating principle | 2-way flow control valve with one fixed setpoint | ||

| Monitoring type | Gear flow meter with pulse sensor | ||

| Installation position | Any (without filter); vertical (with filter) | ||

| Ambient temperature | from 0 to +70 °C | from +32 to +158 °F | |

| Lubricant temperature | from 0 to +70 °C | from +32 to +158 °F | |

| Material | EN AW-6061-T651, anodized | ||

| Weight | 1.17 kg | 2.58 pounds |

|

| Dimensions without monitoring (L×W×H) | 79×79×90 mm | 3.11×3.11×3.54 inches | |

| Nominal flow rate | 0.08–8.0 l/min | 0.17–16.9 pints/min | |

| Working pressure p1 | 5–50 bar | 72.5–725 psi | |

| Required differential pressure (p3-p1) | ≥ 6 bar | ≥ 87 psi | |

| Lubricant | Mineral oils, synthetic oils | ||

| Working viscosity | 20–600 mm2/With | ||

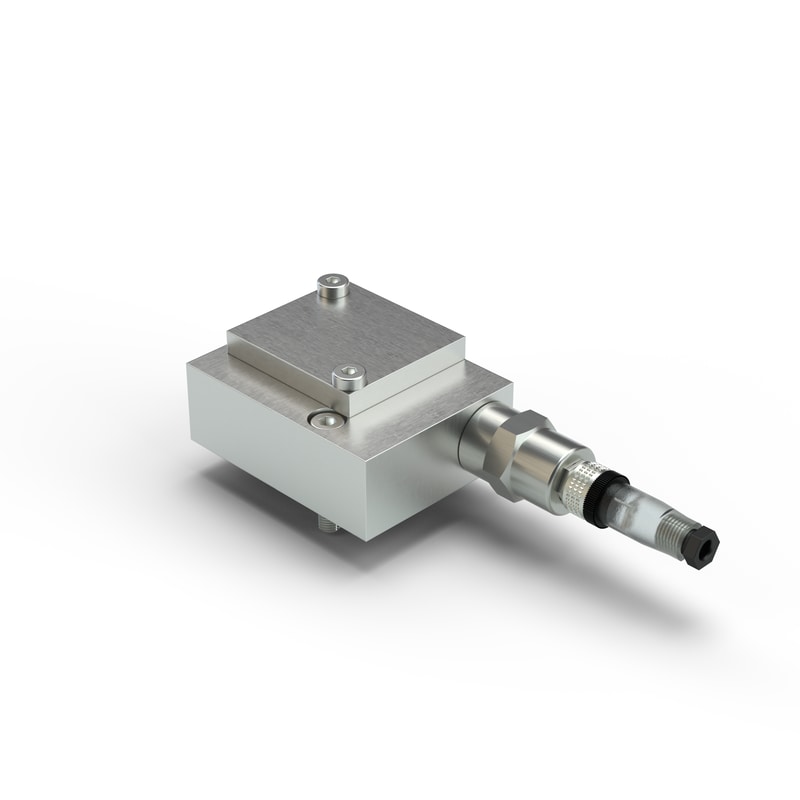

| SMBM-V 21/22 Monitoring with a signal transmitter |

|

SMBM-V 31 Monitoring with a piston sensor |

|

| Type/operating principle | 2-way flow control valve with two separate fixed setpoints | ||

| Monitoring type | Signal sensor or piston sensor (signal present/no) | ||

| Installation position | Any (without filter); vertical (with filter) | ||

| Ambient temperature | from 0 to +70 °C | from +32 to +158 °F | |

| Lubricant temperature | from 0 to +70 °C | from +32 to +158 °F | |

| Material | EN AW-6061-T651, anodized | ||

| Weight SMBM-V 21/22 Weight SMBM-V 31 |

1.03 kg 0.97 kg |

2.27 pounds 2.14 pounds |

|

| Dimensions without monitoring (L×W×H) | 100×79×45 mm | 3.94×3.11×1.77 inches | |

| Nominal flow rate | 0.08–8.0 l/min | 0.17–16.9 pints/min | |

| Working pressure p1 Without electrical monitoring SMBM-V 21/22 SMBM-V 31 |

5–200 bar 5–100 bar 5–85 bar |

72.5–2900 psi 72.5–1450 psi 72.5–1230 psi |

|

| Required differential pressure (p3-p1) | ≥ 5 bar | ≥ 72.5 psi | |

| Lubricant | Mineral oils, synthetic oils | ||

| Working viscosity | 20–600 mm2/With | ||

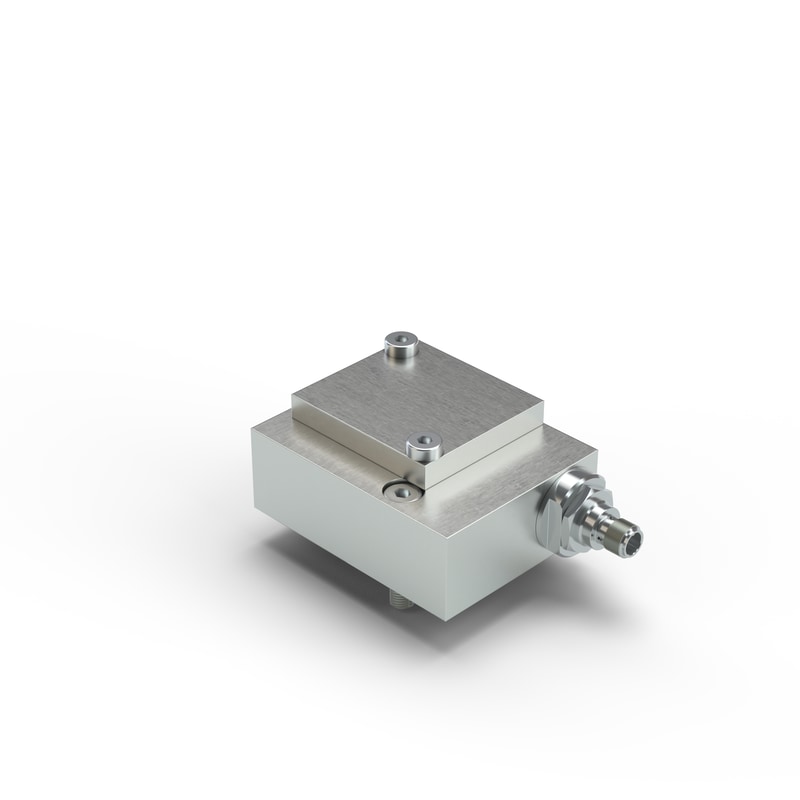

| SMBM-V 11/12/13 Monitoring with a gear flow meter with a threaded pulse sensor |

|

||

| Monitoring type | Gear flow meter with pulse sensor | ||

| Installation position | Any (without filter); vertical (with filter) | ||

| Ambient temperature | from 0 to +70 °C | from +32 to +158 °F | |

| Lubricant temperature | from 0 to +70 °C | from +32 to +158 °F | |

| Material | EN AW-6061-T651, anodized | ||

| Weight | 1.34 kg | 2.95 pounds |

|

| Dimensions without monitoring (L×W×H) | 100×79×90 mm | 3.94×3.11×3.54 inches | |

| Nominal flow rate | 0.08–8.0 l/min | 0.17–16.9 pints/min | |

| Working pressure p1 | 5–50 bar | 72.5–725 psi | |

| Required differential pressure (p3-p1) | ≥ 6 bar | ≥ 87 psi | |

| Lubricant | Mineral oils, synthetic oils | ||

| Working viscosity | 20–600 mm2/With | ||

Designs for use in explosive environments

| SMBM-X …-EEX Monitoring with a gear flow meter with a threaded pulse sensor |

|

||

| Type/operating principle | 2-way flow control valve with one fixed setpoint | ||

| Monitoring type | Gear flow meter with pulse sensor | ||

| Installation position | Any (without filter); vertical (with filter) | ||

| Ambient temperature | from 0 to +70 °C | from +32 to +158 °F | |

| Lubricant temperature | from 0 to +70 °C | from +32 to +158 °F | |

| Material | EN AW-6061-T651, anodized | ||

| Weight | 1.17 kg | 2.58 pounds |

|

| Dimensions without monitoring (L×W×H) | 79×79×90 mm | 3.11×3.11×3.54 inches | |

| Nominal flow rate | 0.08–8.0 l/min | 0.17–16.9 pints/min | |

| Working pressure p1 | 5–50 bar | 72.5-725 psi | |

| Required differential pressure (p3-p1) | ≥ 6 bar | ≥ 87 psi | |

| Lubricant | Mineral oils, synthetic oils | ||

| Working viscosity | 20–600 mm2/With | ||

| SMBM-V …-EEX Monitoring with a gear flow meter with a threaded pulse sensor |

|

||

| Type/operating principle | 2-way flow control valve with two separate fixed setpoints | ||

| Monitoring type | Gear flow meter with pulse sensor | ||

| Installation position | Any (without filter); vertical (with filter) | ||

| Ambient temperature | from 0 to +70 °C | from +32 to +158 °F | |

| Lubricant temperature | from 0 to +70 °C | from +32 to +158 °F | |

| Material | EN AW-6061-T651, anodized | ||

| Weight | 1.34 kg | 2.95 pounds |

|

| Dimensions without monitoring (L×W×H) | 100×79×90 mm | 3.94×3.11×3.54 inches | |

| Nominal flow rate | 0.08–8.0 l/min | 0.17–16.9 pints/min | |

| Working pressure p1 | 5–50 bar | 72.5-725 psi | |

| Required differential pressure (p3-p1) | ≥ 6 bar | ≥ 87 psi | |

| Lubricant | Mineral oils, synthetic oils | ||

| Working viscosity | 20–600 mm2/With | ||

| The product can be configured using a configuration code. The order template includes the applicable part number and an explanation. | |

| SMBM-V11 CS 022 |

|

| SMBM-X22 XS 150 — EEX |

|

| More detailed information is provided in the brochure. | |

Injection nozzles

| Nominal oil consumption 2) | Injector index | Order number | |

| l/min | pints/min | ||

| 0,08 | 0,17 | 050 | 24-0455-2574 |

| 0,12 | 0,25 | 055 | 24-0455-2575 |

| 0,15 | 0,32 | 060 | 24-0455-2576 |

| 0,2 | 0,42 | 065 | 24-0455-2577 |

| 0,25 | 0,53 | 070 | 24-0455-2578 |

| 0,29 | 0,61 | 075 | 24-0455-2579 |

| 0,35 | 0,74 | 080 | 24-0455-2580 |

| 0,41 | 0,87 | 085 | 24-0455-2581 |

| 0,47 | 0,99 | 090 | 24-0455-2582 |

| 0,56 | 1,18 | 095 | 24-0455-2583 |

| 0,65 | 1,37 | 100 | 24-0455-2584 |

| 0,73 | 1,54 | 105 | 24-0455-2585 |

| 0,79 | 1,67 | 110 | 24-0455-2586 |

| 0,88 | 1,86 | 115 | 24-0455-2587 |

| 0,98 | 2,07 | 120 | 24-0455-2588 |

| 1,09 | 2,3 | 125 | 24-0455-2589 |

| 1,18 | 2,49 | 130 | 24-0455-2590 |

| 1,3 | 2,75 | 135 | 24-0455-2591 |

| 1,43 | 3,02 | 140 | 24-0455-2592 |

| 1,56 | 3,3 | 145 | 24-0455-2593 |

| 1,67 | 3,53 | 150 | 24-0455-2594 |

| 1,79 | 3,87 | 155 | 24-0455-2595 |

| 1,92 | 4,06 | 160 | 24-0455-2596 |

| 2,07 | 4,37 | 165 | 24-0455-2597 |

| 2,21 | 4,67 | 170 | 24-0455-2598 |

| 2,36 | 4,99 | 175 | 24-0455-2599 |

| 2,52 | 5,33 | 180 | 24-0455-2600 |

| 2,67 | 5,64 | 185 | 24-0455-2601 |

| 2,8 | 5,92 | 190 | 24-0455-2602 |

| 2,98 | 6,3 | 195 | 24-0455-2603 |

| 3,16 | 6,68 | 200 | 24-0455-2604 |

| 3,3 | 6,97 | 205 | 24-0455-2605 |

| 3,43 | 7,25 | 210 | 24-0455-2606 |

| 3,58 | 7,57 | 215 | 24-0455-2607 |

| 3,79 | 8,01 | 220 | 24-0455-2608 |

| 3,98 | 8,22 | 225 | 24-0455-2609 |

| 4,18 | 8,83 | 230 | 24-0455-2610 |

| 4,37 | 9,24 | 235 | 24-0455-2611 |

| 4,57 | 9,66 | 240 | 24-0455-2612 |

| 4,8 | 10,14 | 245 | 24-0455-2613 |

| 5 | 10,57 | 250 | 24-0455-2614 |

| 5,19 | 10,97 | 255 | 24-0455-2615 |

| 5,37 | 11,35 | 260 | 24-0455-2616 |

| 5,55 | 11,73 | 265 | 24-0455-2617 |

| 5,77 | 12,19 | 270 | 24-0455-2618 |

| 5,99 | 12,66 | 275 | 24-0455-2619 |

| 6,22 | 13,15 | 280 | 24-0455-2620 |

| 6,49 | 13,72 | 285 | 24-0455-2621 |

| 6,74 | 14,24 | 290 | 24-0455-2622 |

| 6,95 | 14,69 | 295 | 24-0455-2623 |

| 7,17 | 15,15 | 300 | 24-0455-2624 3) |

| 7,31 | 15,45 | 305 | 24-0455-2625 3) |

| 7,48 | 15,81 | 310 | 24-0455-2626 3) |

| 7,72 | 16,32 | 315 | 24-0455-2627 3) |

| 7,98 | 16,86 | 320 | 24-0455-2628 3) |

| Nominal oil consumption 2) | Injector index | Order number | ||

| l/min | pints/min | Injector D1 | Injector D2 | |

| 0,08 : 0,65 | 0,17 : 1,37 | 003 | 24-0455-2574 | 24-0455-2584 |

| 0,12 : 0,79 | 0,25 : 1,67 | 004 | 24-0455-2575 | 24-0455-2586 |

| 0,15 : 0,98 | 0,32 : 2,07 | 005 | 24-0455-2576 | 24-0455-2588 |

| 0,20 : 1,18 | 0,42 : 2,49 | 006 | 24-0455-2577 | 24-0455-2590 |

| 0,25 : 1,43 | 0,83 : 3,02 | 007 | 24-0455-2578 | 24-0455-2592 |

| 0,29 : 1,67 | 0,61 : 3,53 | 008 | 24-0455-2579 | 24-0455-2594 |

| 0,35 : 1,92 | 0,74 : 4,06 | 009 | 24-0455-2580 | 24-0455-2596 |

| 0,41 : 2,21 | 0,87 : 4,67 | 010 | 24-0455-2581 | 24-0455-2598 |

| 0,47 : 2,52 | 0,99 : 5,33 | 011 | 24-0455-2582 | 24-0455-2600 |

| 0,56 : 2,80 | 1,18 : 5,92 | 012 | 24-0455-2583 | 24-0455-2602 |

| 0,65 : 3,16 | 1,37 : 6,68 | 013 | 24-0455-2584 | 24-0455-2604 |

| 0,73 : 3,43 | 1,54 : 7,25 | 014 | 24-0455-2585 | 24-0455-2606 |

| 0,79 : 3,79 | 1,67 : 8,01 | 015 | 24-0455-2586 | 24-0455-2608 |

| 0,88 : 4,37 | 1,86 : 9,24 | 016 | 24-0455-2587 | 24-0455-2610 |

| 0,98 : 4,57 | 2,07 : 9,66 | 017 | 24-0455-2588 | 24-0455-2612 |

| 1,09 : 5,00 | 2,30 : 10,57 | 018 | 24-0455-2589 | 24-0455-2614 |

| 1,18 : 5,37 | 2,49 : 11,35 | 019 | 24-0455-2590 | 24-0455-2616 |

| 1,30 : 5,77 | 2,75 : 12,19 | 020 | 24-0455-25 91 | 24-0455-2618 |

| 1,43 : 6,22 | 3,02 : 13,15 | 021 | 24-0455-2592 | 24-0455-2620 |

| 1,56 : 6,74 | 3,30 : 14,24 | 022 | 24-0455-2593 | 24-0455-2622 |

| 1,67 : 7,17 | 3,53 : 15,15 | 023 | 24-0455-2594 | 24-0455-2624 4) |

| 1,79 : 7,48 | 3,87 : 15,81 | 024 | 24-0455-2595 | 24-0455-2626 4) |

| 1,92 : 7,98 | 4,06 : 16,86 | 025 | 24-0455-2596 | 24-0455-2628 4) |

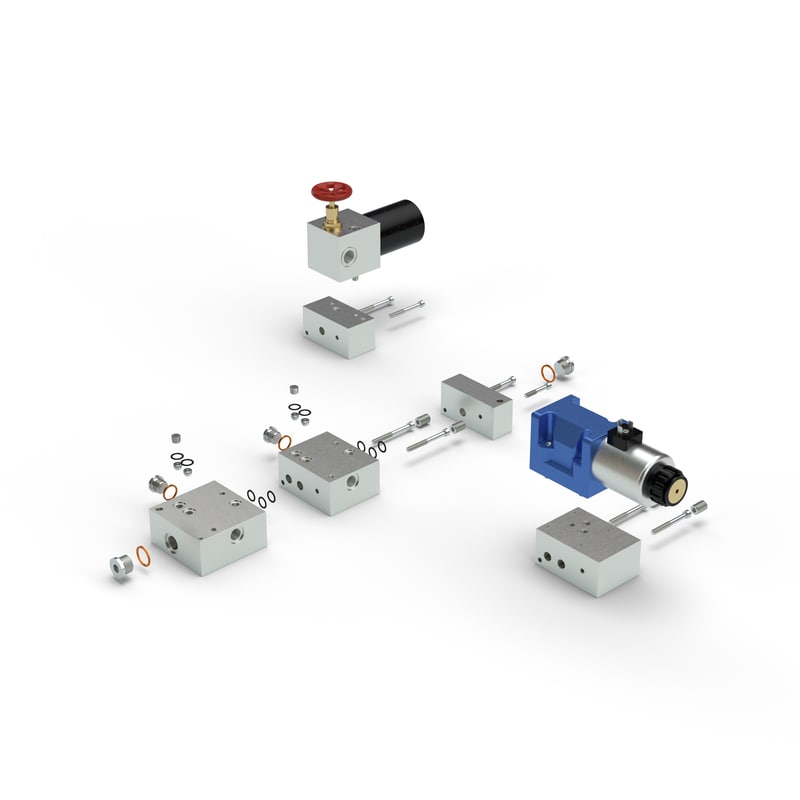

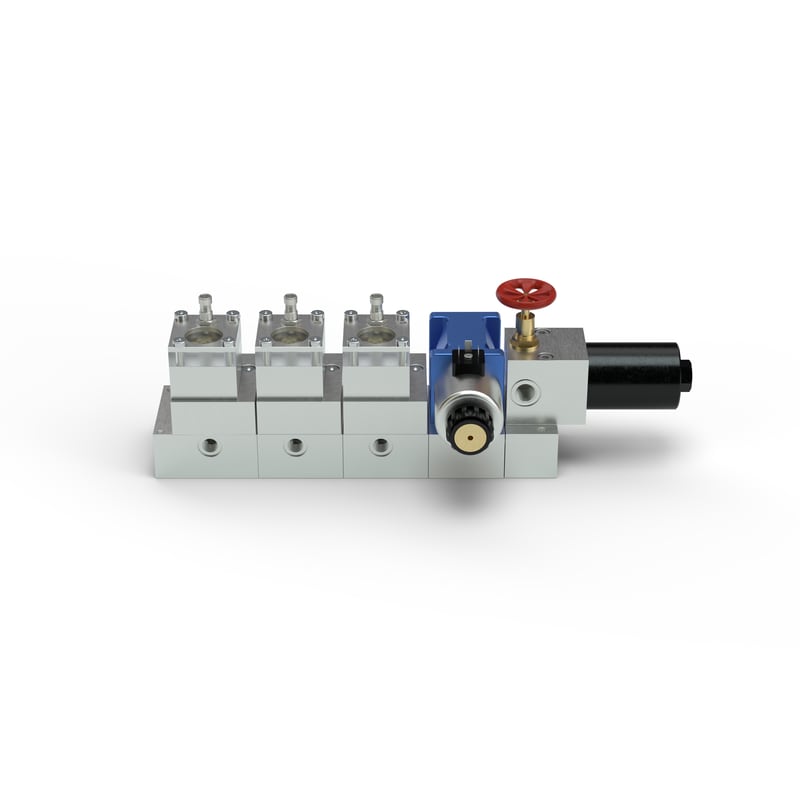

Support panels for flow limiters of all designs

| Flow limiter support panels can be adjusted to meet specific requirements. Their modular design allows for various combinations.

To create a complete support panel, at least two modules are required:

|

|

| This combination can be used to install one flow limiter module of the series SMBM-X If a filter is required, a filter setting segment can be used instead of a simple input segment.

To install more than one flow restrictor module, an extension segment must be installed between the inlet segment or filter mounting segment and the base segment. For the series SMBM-V An additional segment is required to install the valve between the inlet segment or filter installation segment and the first extension segment or base segment. |

| Material | EN AW-6061-T651 anodized |

| Lubricant inlet | G1/2 |

| Lubricant outlet | G3/8 |

| Support panel | Length | Width | Height | Weight | Order number | ||||

| mm | inches | mm | inches | mm | inches | kg | pounds | ||

| Base segment | 98,5 | 3,88 | 100 | 3,94 | 48 | 1,89 | 1,10 | 2,43 | 24-0714-3483 |

| Extension segment | mm | inches | 100 | 3,94 | 48 | 1,89 | 1,00 | 2,21 | 24-0714-3484 |

| Input segment | mm | inches | 100 | 3,94 | 48 | 1,89 | 0,47 | 1,04 | 24-0714-3485 |

| Segment for valve installation | mm | inches | 100 | 3,94 | 48 | 1,89 | 0,91 | 2,01 | 24-0714-3486 |

| Segment for filter installation | mm | inches | 100 | 3,94 | 48 | 1,89 | 0,64 | 1,41 | 24-0714-3487 |

| To order a pre-assembled flow restrictor group, each module must be configured using an order code. Modules are numbered according to installation order. A diverter valve will be added if required for one or more selected modules. The maximum number of modules allowed is six. | ||

| SMBM-V11 CS 022 |  |

|

| More detailed information is provided in the brochure. | ||

Accessories and spare parts 1)

| Product group | Description | Order number |

| Flow limiter housing | SMBM-X without plug-in injectors | 24-0711-2800 |

| SMBM-V without plug-in injectors | 24-0711-2801 | |

| Signal transmitter (standard version) | Incl. straight connector (24VDC), M12x1, LED type | 24-1072-2115 |

| Includes straight connector (24VDC), M12x1 | 24-1072-2114 | |

| Without connector | 24-1072-2123 | |

| Straight connector (24VDC), M12x1, LED type | 24-1882-2151 | |

| Straight connector (24VDC), M12x1 | 24-1882-2121 | |

| Straight connector (24VDC), M12x1, LED type, with 5m cable | 179-990-604 | |

| Angled connector (24V DC), M12x1, LED type, with 5m cable | 237-10319-2 | |

| Signal transmitter (ATEX version) 1) | Incl. straight connector (30 V), ATEX version, M12x1 | 24-1072-2116 |

| Including straight connector, 2-pole, M12x1, with 5 m cable | 24-1882-5005 | |

| Incl. angled connector, 2-pole, M12x1, with 15 m cable | 24-1882-5016 | |

| Piston sensor | Without connector | 24-1884-2785 |

| Straight connector, 3-pole, M12x1, with 5 m cable | 179-990-381 | |

| Angled connector, 3-pole, M12x1, with 5 m cable | 179-990-382 | |

| Straight connector, 4-pole, M12x1 | 179-990-371 | |

| Angled connector, 4-pole, M12x1 | 179-990-372 | |

| Gear flow meter (standard version) | For SMBM-X/-V 11 (333 imp/l) | 24-0711-2816 |

| For SMBM-X/-V 12 (167 imp/l) | 24-0711-2811 | |

| For SMBM-X/-V 13 (83 imp/l) | 24-0711-2812 | |

| Standard pulse sensor M12x1 | 2340-00000030 | |

| Straight connector, 3-pole, M12x1, with 2 m cable | 2370-00000053 | |

| Straight connector, 3-pole, M12x1, with 5 m cable | 179-990-381 | |

| Angled connector, 3-pole, M12x1, with 5 m cable | 179-990-382 | |

| Straight connector, 4-pole, M12x1 | 179-990-371 | |

| Angled connector, 4-pole, M12x1 | 179-990-372 | |

| Gear flow meter (ATEX version) | For SMBM-X/-V 11 (333 imp/l) EEX | 24-0711-2813 |

| For SMBM-X/-V 12 (167 imp/l) EEX | 24-0711-2814 | |

| For SMBM-X/-V 13 (83 imp./l) EEX | 24-0711-2815 | |

| Pulse sensor M12x1 standard EEX | 2340-00000091 | |

| Straight connector, 2-pole, M12x1, with 5 m cable | 24-1882-5005 | |

| Straight connector, 2-pole, M12x1, with 15 m cable | 24-1882-5016 | |

| Monitoring units | Group monitoring unit (signal transmitter and gear sensor SMBM-X/-V) | 84-8011-0369 |

| IPM-12 pulse monitoring unit (version of SMBM-X/-V gear flow meter) | 84-8011-0380 | |

| IPM-12 Pulse Monitoring Unit (84-8011-0380) with M12 Connector | 84-8011-0390 | |

| Changeover valves (standard version) | 24VDC Electric Diverter Valves | 24-1254-2486 |

| 24V DC connector as a spare part with built-in rectifier | 24-1882-2029 | |

| Changeover valves (ATEX version) | 24VDC Electric Diverter Valves | 24-1254-3437 |

| Adapter (must be ordered with valve) | 24-1503-2552 | |

| Filter | Oil filter with shut-off valve | 24-0651-3041 |

| Valve cover with flywheel | 24-2104-2009 | |

| Filter element 100 microns | 24-0651-2200 | |

| Seal kits | Seal kit for gear flow meter | 24-0404-2644 |

| Seal kit for base segment | 24-0404-2645 | |

| Seal kit for extension segment | 24-0404-2646 | |

| Seal kit for valve mounting segment | 24-0404-2647 | |

| Filter seal kit | 24-0404-2293 | |

| Seal kit for top access connection module | 24-0404-2648 | |

| Seal kit for changeover valve (ATEX version) | 24-0404-2639 | |

| Support panels | Base segment | 24-0714-3483 |

| Extension segment | 24-0714-3484 | |

| Input segment | 24-0714-3485 | |

| Segment for valve installation (changeover valve must be ordered separately) | 24-0714-3486 | |

| Segment for filter installation (filter valve must be ordered separately) | 24-0714-3487 | |

| Top-access connection module | 24-0714-3440 | |

| Plug for empty positions of flow limiter | 24-0711-2406 | |

| Inlet plug G1/2 | 95-0012-0908 | |

| Copper washer for inlet plug G1/2 | DIN7603-A21X26-CU | |

| Outlet plug G3/8 | 95-0038-0908 | |

| Copper washer for outlet plug G3/8 | DIN7603-A17X21-CU | |

| O-ring 12×2, for base segment, extension and filter, for SMBM-X and SMBM-V modules | WVN532-12X2 | |

| Check valve, 2 pieces required only for base and extension segments with SMBM-V | 24-2104-2049 | |

| Check valve installation tool 24-2104-2049 | 2350-00000078 | |

| End cap R 1/8, 1 piece required only per base and extension segment with SMBM-X | 2030-00000002 | |

| Connecting screw for installing the support panel (spare part) | 44-1821-2588 | |

| Mounting screw for installing the support panel, input segment (spare part) | DIN912-M6X40-8.8 | |

| Mounting screw for installing the support panel (spare part) | DIN912-M6X65-8.8 | |

| Mounting screw for installing the support panel, valve segment and filter (spare part) | DIN912-M6X60-8.8 | |