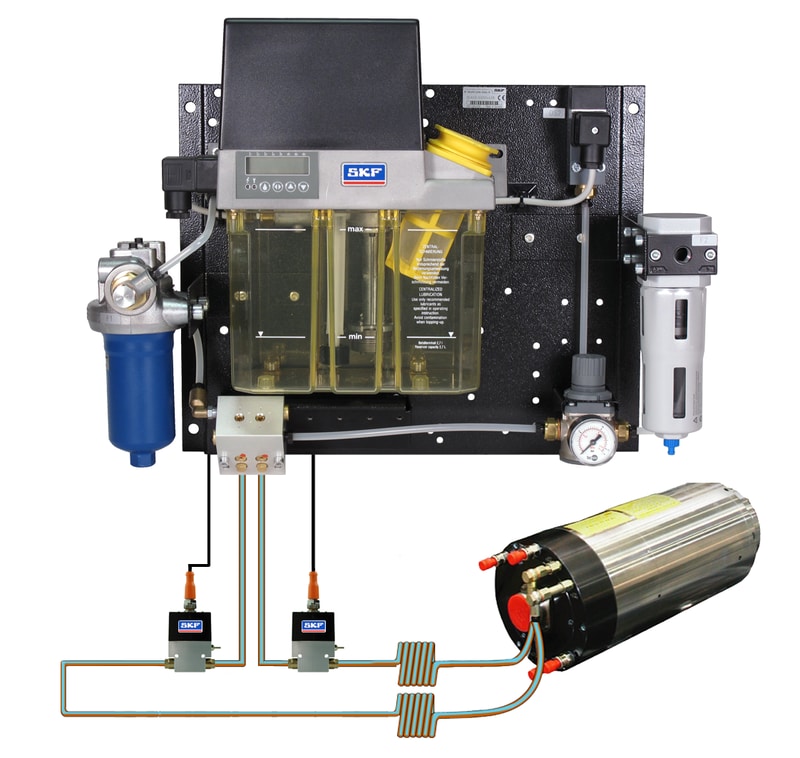

Oil-air lubrication units

The air flow in a narrow tube separates the oil droplets and forms streams that move to the lubrication point. Through the nozzle, oil is continuously supplied to the bearing in the form of fine droplets. The air supplying the oil exits the bearing virtually free of oil droplets.

Components are supplied assembled (model OLA) or individually. Ordering components individually makes sense if the lubrication system will not be installed on the machine as a single unit (for example, due to space constraints).

Criteria for distinction

- Improved machining performance when lubricating spindle bearings thanks to higher speed parameters

- Increased reliability thanks to the continuous supply of a predetermined amount of lubricant. The air supplied by the system protects the bearings from external contaminants.

- Lower lubricant consumption contributes to improved safety and environmental protection

- Controlled dosing for each lubrication point allows savings of approximately 90 % of lubricant compared to oil lubrication

- No oil mist, no need to refill with grease as with plastic grease lubrication

Application areas

- Lubrication of spindle bearings

- Chain lubrication

- Lubrication of gears

- Lubrication of guides

- Lubrication of assembly and process devices