Sequential lubrication systems

For small and medium-sized equipment requiring continuous lubrication

Sequential systems provide continuous lubrication throughout the pump's operation. When the pump stops, the pistons of the sequential metering device also stop. When the pump resumes supplying lubricant, the pistons resume their motion from the position they stopped. Thus, the sequential circuit of one pump outlet stops when one lubrication point is blocked. The blockage serves as a monitoring device and alerts personnel to the need for system maintenance.

Visual or electrical monitoring can be performed for only one output of the primary or secondary metering device connected to one pump outlet, depending on the metering device selected.

Advantages

- Continuous lubrication is the frequent supply of a measured amount of lubricant to each lubrication point.

- Reliable monitoring and control - simple system monitoring and blocking control, integrated control and monitoring system

- Effective operation in difficult conditions with potentially high back pressure at lubrication points, contaminated, humid environments (including ATEX / EEX) and low temperatures.

Application areas

- Construction equipment (pumps for concrete and mortar, loaders, excavators, trenchers)

- Road trucks (snow removal, waste compactor)

- Agricultural machinery (combine harvesters, balers, fertilizer spreaders, sugar cane loaders)

- Log throwers

- Loading and unloading operations (container loaders, crane trucks)

- Asphalt mixing plants

- Wind turbine generators

- Food and beverage production (fillers, washers)

- Piston compressors in the oil and gas industry

Description

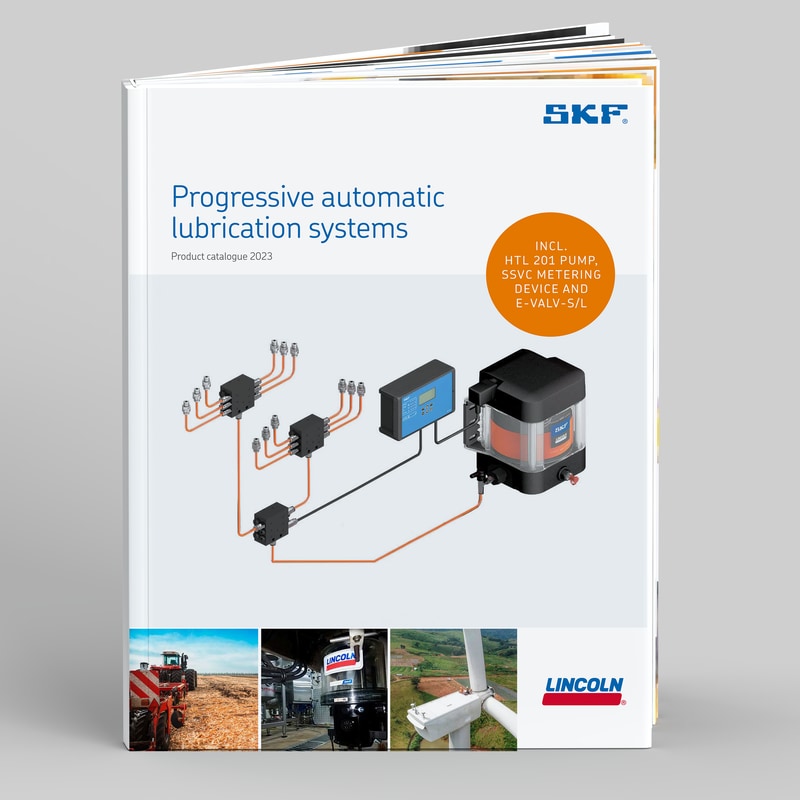

SKF ProFlex and Lincoln Quicklub progressive lubrication systems are used in small and medium-sized equipment with dispersed lubrication points that require different amounts of lubricant.

Sequential systems include a pump connected to at least one primary metering device. If necessary, secondary metering devices can be connected to the primary metering device's outlets to increase the number of lubrication points. The outlets of the primary and secondary metering devices are connected via branch lines to the equipment's lubrication points. The use of a third level of metering devices is not recommended. The pump delivers lubricant to the metering devices at pressures up to 550 bar. (8000 psi) depending on the pump model.

Metering devices divide the lubricant into equal or predetermined volumes. The volume of lubricant dispensed from each outlet of the metering device depends on the type of metering device used.

Sequential systems provide precisely dosed amounts of lubricant to up to 150 lubrication points over a distance of approximately 15 m. (16 yards).

Operating principle

Lubrication system components

Pumps and pumping units

Dosing devices for lubricants

Monitoring devices

Control units and software

Accessories