Multi-line lubrication systems

For heavy-duty applications in virtually all industries

Multi-line pump units deliver lubricant to lubrication points without the need for additional metering devices. Each lubrication point is equipped with its own pump element. The system features a simple and highly reliable design. Multi-line pumps can be driven mechanically, electrically, or hydraulically. Easily replaceable pump elements are typically controlled by an eccentric cam. By selecting pump elements with different piston diameters and/or piston stroke settings, the lubricant delivery to each pump outlet can be individually adjusted.

Advantages

- Durability is a series of pumps designed for 24/7 operation.

- Simplicity - continuous lubrication, in most cases without electrical cycle timers

- Versatility – the ability to select individual pump characteristics and oil tank volume

- Accuracy - setting the required flow volume for the pump element

- Works in a wide range of viscosities due to a special design and small piston clearance

- ATEX explosion-proof versions are available

- Additional low pressure valves or sequential metering devices located further down the pipeline may be installed.

Application areas

- Lubrication of vacuum pumps, compressors (all types) and hypercompressors

- Lubrication of valves and cylinders of internal combustion engines

- Critical applications with continuous oil lubrication or small circulating oil lubrication systems

- Rubber mixing equipment, supply of plasticizers

- Construction and mining equipment

- Tunnel boring machines

- Forging, bending, stamping and cutting presses

- Crushers, cranes and conveyors

- Pumps and compressors

- Rubber mixing equipment

- Water and slurry pumps

- Compliance with ATEX and API standards

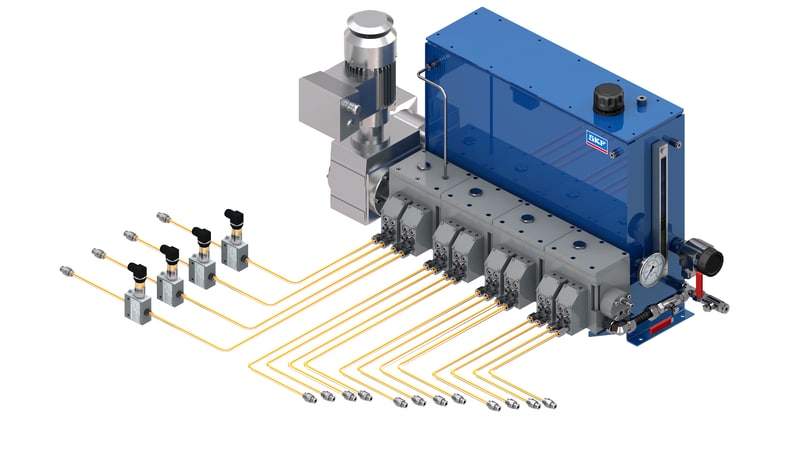

Multi-line oil lubrication systems

Description of multi-line oil lubrication systems

Multi-line oil lubrication systems consist of the following components: a pump unit, control and monitoring devices, piping, and fittings. Multi-line pump units deliver lubricant to lubrication points without the use of additional metering devices. Therefore, each lubrication point is equipped with its own pump element. The system is characterized by a simple and highly reliable design.

Multi-line pumps can be driven mechanically, electrically, or hydraulically. Easily replaceable pump elements are typically controlled by an eccentric cam. Depending on the drive speed, gear ratio, and selected pump element size, the delivery volume can vary from virtually 0 to 227 cm3.3/min (0 to 13.85 inches3/min). By selecting pump elements with different piston diameters and/or piston stroke settings, the lubricant delivery to each pump outlet can be individually adjusted. The potential number of outlets ranges from 1 to 28.

SKF multi-line oil pumps are designed for heavy-duty applications in virtually all industries, with pressure requirements up to 4,000 bar. (58,000 psi).

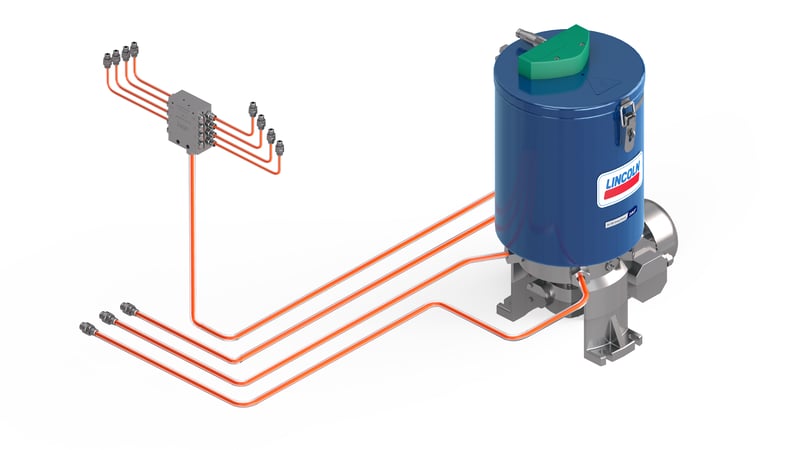

Multi-line lubrication systems for greases up to NLGI grade 3…

Description of multi-line grease lubrication systems

Multi-line grease pumps can be driven mechanically, electrically, or hydraulically. Easily replaceable pump elements are typically controlled by an eccentric cam. Depending on the drive speed, gear ratio, and selected pump element size, the delivery volume can vary from virtually 0 to 35 cm3.3/min (0 to 2.13 inches)3/min). The integrated agitator stirs the grease (softening the grease), synchronizes with the pump element's suction stroke, and helps the heavy grease descend into the suction chamber. This unique concept pumps heavy lubricants, typically up to NLGI grade 3.

Customization of the lubricant volume at the pump outlet is possible by selecting pump elements with different piston diameters and/or stroke settings. The potential number of outlets varies from 1 to 30. SKF multi-line lubrication pumps are designed for operation under severe conditions in virtually all industries. Most pump models are available with special oil reservoirs. The P 215 and P 230 series pumps can be used with plasticizer oils for the rubber industry.

Lubrication system components

Pumps and pumping units

Dosing devices for lubricants

Monitoring devices

Control units and software

Accessories