Minimum quantity lubrication systems

For lubrication during high-speed cutting operations

Machine operators can significantly reduce production costs by using SKF minimum quantity lubrication systems. These systems ensure longer tool life and improved product quality through more precise surface finishes. Since minimum quantity lubrication systems do not require coolant, they eliminate the cost of coolant, associated filters, preparation systems, and disposal. Furthermore, there is no need to clean the workpiece or chips.

Advantages

- Increasing the service life of cutting tools

- Increased productivity at higher cutting speeds

- Reducing maintenance costs

- Improving the quality of the treated surface

- Reduced energy consumption and CO2 emissions

Application areas

- Milling

- Rolling

- Cutting

- Drilling

- Boring

- Molding

Minimum quantity lubrication systems

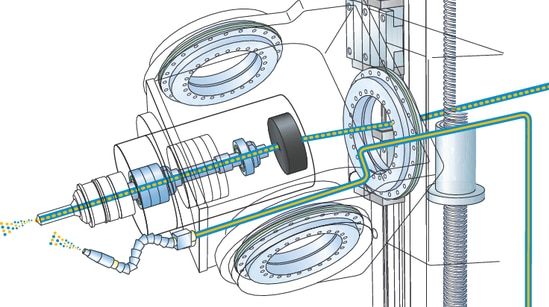

With the internal lubrication method, compressed air or oil mist is supplied through the spindle, tool holder and tool directly between the tool and the workpiece.Minimum quantity lubrication with internal lubricant supply:

Minimum quantity lubrication with external lubricant supply:

You need to know your limits

Minimum quantity lubrication units

Explore our product range